A retail center lifestyles or dies by uptime. Doors need to have to open up, trucks need to have to unload, and clients expect amount floors as well as operating stores, certainly not care tape around a split piece. This instance fixates a 120,000 square feet retail structure built in the overdue 1990s on a site that looked great theoretically, but lugged a subsurface story no geotechnical engineer just likes to inform twice. Over fifteen years the job wandered away from level, opening gaps in exterior joints, tiing storefront doors, and telegraphing a fracture network with the internal piece. The owner had actually patched as well as wished years, consisting of episodic epoxy injections as well as aesthetic piece repair work, but the activity always kept returning. When the anchors of 3 resident rooms headed out of tolerance, the facility's resource manager carried us belong one direction: support it without shutting the place down.

What observes is actually an inside consider the examination, design, as well as execution of deep foundation repair utilizing helical piles as well as helical tieback anchors on an energetic office website. I will cover what worked, what our company changed as soon as we opened the ground, and why helical devices pounded various other possibilities for this certain work. I will definitely likewise touch on where micropiles and protection heaps still make sense, because there is no single hammer that matches every nail.

The signs and symptoms that triggered the call

You may normally discriminate in between an annoyance gap and structural distress through just how it behaves over periods. In this particular center, junctions at the block laminate consistently widened outboard and also closed somewhat inboard, a sign the boundary was actually rotating. Pair of occupants mentioned that brand-new plaster fracture fixings would certainly come back within months, constantly near the frontal glazing line. The locations staff possessed ground down door thresholds much more than when to always keep doors moving.

We ran a flooring altitude survey on a 10 foot grid during off hrs. The worst edge was down 1.75 inches relative to a central internal objective. The main facade along the south elevation possessed a steady descending incline of regarding 0.6 percent towards the car park. Outside, the sidewalk had actually created a "smile" where downspouts released, an idea our company usually see when roof overflow shifts towards the slab side. The side that faced an apprehension basin presented the deepest movement.

Early on, our company reckoned the initial spread footings were actually sitting partly on channel heavy fill over compressible indigenous clay, along with occasional lenses of organics near the aged drain swale. That is actually a risky club sandwich for a shallow structure, specifically when landscape design and watering raise the moisture information at the edges. The utility concern was crystal clear: the perimeter was actually shedding help. The question ended up being exactly how deep our company had to go to locate competent bearing, and also how to do it while the establishments stayed open.

Commercial Helical Pile InstallationSite examination that mattered

Paperwork aids, but the borings from the 1990s left our company with larger selections than we fit with. Our company took four brand-new borings as well as 2 conoid seepage exams along the south as well as west facades where action was greatest. The soil account associated our uncertainty: about 6 to 9 feet of regulated fill of blended structure, underlain by 8 to 15 feets of smooth to tool plastic clay-based. Listed below twenty to 24 feet, the CPT pointer protection leapt, leading to a dense silty sand coating along with occasional gravel seams. Groundwater was actually seasonal around 7 to 9 feet.

One issue stood out: the existing footing bases were actually simply at 4 feets below grade along the border, as well as the slab bore straight on level. That gave our team little embedment and also unsatisfactory confinement in the area most impacted by seasonal humidity variation.

With those information aspects, our experts built a preliminary target that any deep structure solution required to cultivate capability below 25 feets, ideally latching into the heavy layer near 30 feet. That specified show business for making a decision in between helical piles, resistance stacks, or micropiles.

Choosing helical piles over various other serious foundation options

We examined three families of options as well as examined all of them against the internet site states as well as the functional limit that the retail facility had to keep trading.

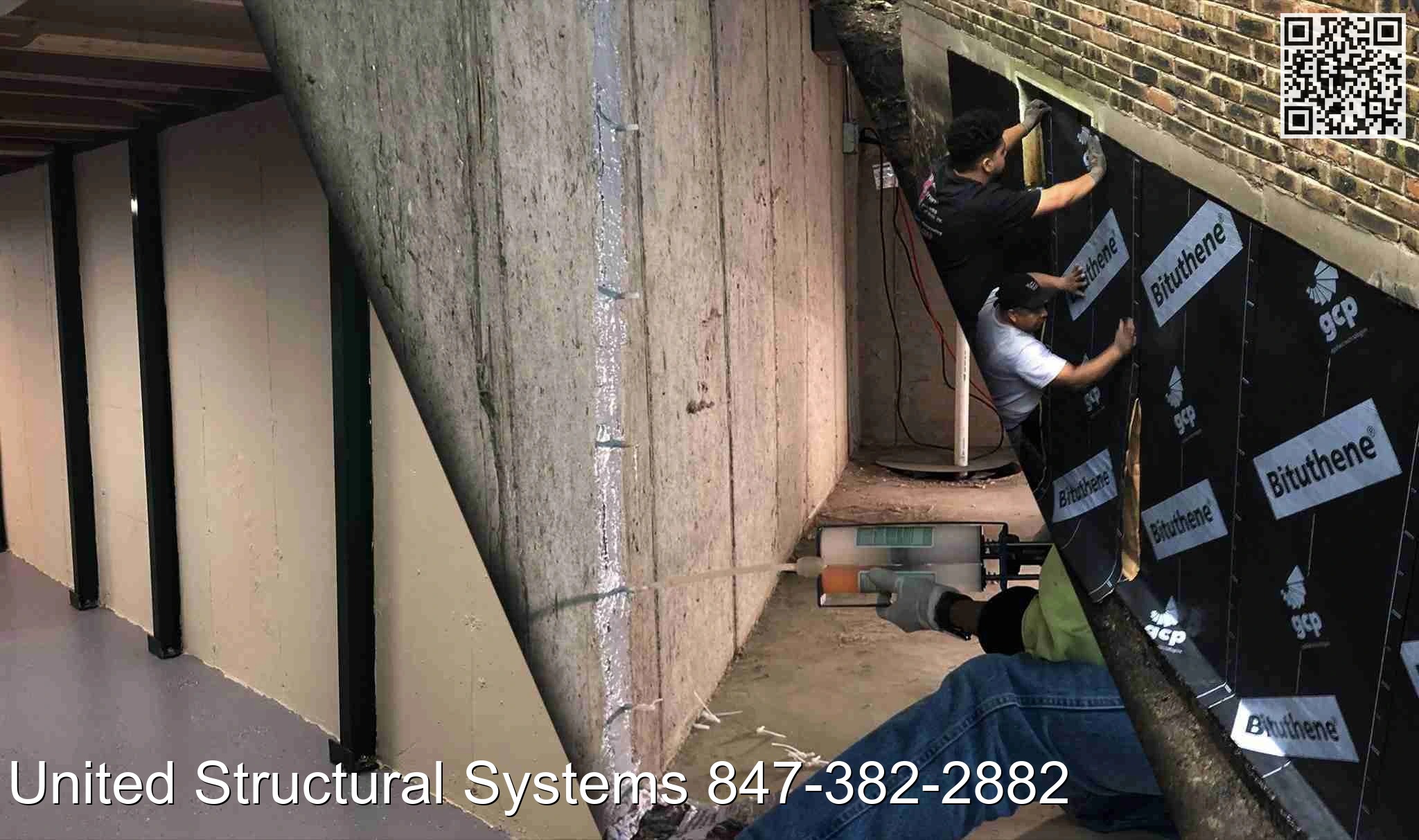

- Commercial helical pile setup uses a silent, low-vibration, torque-controlled method of setting up strong components along with quick load capability. That matters when tenants operate ins far from the work. Helical piles thrive in mixed soils and also could be advanced rapidly with tiny tools. For this internet site, where we needed to interweave around storefronts, vehicle attires, and utility corridors, the tiny footprint mattered. Commercial resistance pile setup, often called push piles or hydraulically driven steel stacks, may also be actually set up with portable equipment. They use the property as reaction to push portions to refusal. They shine when there is a very clear, stiffer stratum to drive into and when accessibility allows a sound reaction framework. On this venture, the variable filler and clay sandwich made irregular driving conditions. The store framing was actually not made to be a trusted reaction source without short-term supporting, which will possess obstructed pedestrian traffic. Commercial micro pile installation (micropiles) delivers higher axial capability via grout-bonded steel in drilled gaps, often with really small dimensions. Micropiles take care of cobbles as well as stones that may cease helicals, as well as they are actually trusted in precarious city internet sites where sound and also resonance limitations are rigorous. Nonetheless, micropile installation demands punching rigs, mess up monitoring, cement combining and positioning, and cure time prior to bunch move. The hosting footprint and damp field part were certainly not best for an active retail frontage.

Given the necessity for velocity, very little resonance, immediate weight capacity, and portable hosting, commercial helical pile installation became our main road. Our team maintained micropiles as a backup if our team struck refusal above the aim at layer or even come across unpredicted blockages that helicals could possibly certainly not traverse. Protection stacks fell out of the flowing the moment we verified the reaction and ride irregularity issues.

Design method: capability, toughness, and also activity targets

The proprietor's brief was easy yet asking for: quit the settlement, recuperate as a lot altitude as sensible without detrimental finishes, as well as stop a replay. Virtual that translated to three numbers our company can gauge: net allowed lots every pile, lift limitations throughout removal, and long-term curvature under service loads.

We created helical piles to work in squeezing under the border grounds, with helical tieback anchors for sidewise security at the packing dock preserving wall that had begun to spin. The decided on helical pile featured a 2.875 in shot pole with a tri-helix lead section, 10, 12, and also 14 inch coils spaced to decrease communication. Our company targeted a minimal torque relationship representing 40 to 50 kips permitted per heap, based upon local torque-to-capacity ratios verified by load exams on similar grounds. Load durations were anticipated in the 28 to 36 feet variation to totally seating in to the heavy sand layer.

Steel was hot-dipped galvanized for rust security, which includes cost however pays where periodic humidity and deicing sodiums exist. We made flexible brand-new building and construction braces tweaked for retrofit to bear under the spreading footing sides after local area underpinning wallets were actually reduced. The bracketry made it possible for alright vertical control as well as promoted staged jacking.

For the packing dock wall structure, we indicated commercial helical tieback anchor installation with 1.75 inch square cylinder anchors and 10 as well as 12 in helix layers. Aim at connect regions were 22 to 28 feet back from the wall face, below the active area, along with workload around 25 kips per tieback. Provided the lumpy layer at deepness, the helical anchors delivered foreseeable installment torque and urgent lock-off.

We established a lift aim for of 0.5 to 1.0 inch at one of the most impacted store fronts with stern tracking. Gyp partitions and store front frames can tolerate moderate changes, however much older glazing and Article source breakable tile are actually unrelenting. Our company prepped the manager that some cosmetic repair services would certainly still be required, as well as in 2 renter areas our experts discussed short-term store front deglazing to permit measured jacking without glass stress.

Phasing the work around operations

The ideal design fails if you may not implement without closing down commerce. Our team damaged the task into 6 portions to ensure no greater than one major lessee gulf per segment would be impacted each time. Job hours ran from 10 p.m. to 8 a.m. for indoor groundwork as well as coming from 5 a.m. to 2 p.m. for outside heap setup near public places, along with momentary barricades as well as scouts handling pedestrian circulations throughout opening up hours.

Utilities dictated the choreography. The principal fire line operated within 6 feets of the south front. Our experts pothole-verified its location at each prepared heap setting, at that point moved 2 heaps by 18 ins and also adjusted brace space to preserve load road balance. Our experts also collaborated with the landscaper to clear away hedges at fifteen sites, which conserved hours wrestling with root rounds during evening shifts.

Noise was actually reasonable considering that helical setup is actually a torque method instead of collision, yet we still utilized rubber keep tracks of as well as laid down mats to safeguard paving and also decrease vibration. The devices lineup consisted of a small excavator with a high-torque ride head, a skid steer for product dealing with, and mobile power generators for lighting.

Installation: the many things you only understand when you carry out it

Paper layouts suppose uniformity that ground never honors. On our 1st section our experts reached 2 surprises and also created 3 corrections that boosted the remainder of the project.

First, the twist surges our experts tape-recorded at 18 to 20 feets were actually not the rich coating our experts looked for. They came from a gravelly change with periodic cobbles. The threat along with helicals is actually slowing or even misleading rejection if a solitary helix remains on a cobble. Our staff progressed with by oscillating and reaming a little, at that point adding a top along with a different helix space for two piles that continued slowing. That versatility is one explanation I as if modular helical bodies for business base stabilization.

Second, our company found a deserted electric conduit right where brace wallets needed to become cut. Checking missed it due to obstruction from neighboring metal shelving. We rerouted brace positions, at that point included one added overdo a quick footing sector to keep eccentricity within limitations. Area judgment like that maintains the repair service truthful. If you move help, you readjust counts.

Third, reaction as well as airlift sequencing concern. You do not mount a 50 shoe run of store in one go. Our experts set up all the turn in a segment, set braces, preloaded each by regarding 5 kips to chair components, then removed in little increases in a leapfrog design. Dial indicators viewed footing motion at 4 spots every segment, and laser device degrees tracked piece as well as store structures. We stopped removing promptly if a gap opened up or a framework squeaked more than endurance. In two places we attained just 0.4 inch of recuperation instead of a full in because the appearances started to fuss. Managers value a service provider that knows when to stop.

When putting up the helical tieback anchors at the loading dock wall, the 1st support pushed with a sand lense and also refused to develop the twist our company wished. Our company extended the anchor duration through one section to reach out to the designated dense level, at that point reconsidered positioning. All anchors were assessed to 150 per-cent of concept bunch and secured off, as well as the wall activity stabilized within machinery sound after 2 weeks.

Addressing structure cracks as well as internal distress

Helical stacks and also tieback anchors cease the source, yet tenants still view the results in their spaces. Our experts partnered with a specialty staff for foundation crack repair simply after the framework was actually maintained and also lift objectives met. Epoxy shot makes sense on architectural gaps in footings and also grade beams when you recognize motion has ceased. For slab-on-grade gaps that are non-structural, directing and also closing with a versatile polyurea is actually a much better bet. Inflexible epoxies in a lifestyle retail atmosphere usually telegram with floor tile or vinyl slab later, and also the design yields with thermal cycles.

We worked with the injection timetable along with nighttime functioning windows. The workers sewed a few obstinate piece splits with carbon dioxide fiber bands around support manners to avoid re-opening. Along the front, we totally reset block control joints where the largest voids had actually developed, as well as we re-caulked all perimeter joints with a high-performance sealant. The occupants observed the distinction when thresholds smoothed and doors ceased rubbing.

Performance proof as well as monitoring

There is a tendency in our industry to announce victory the time the workers demobilizes. I do not depend on any sort of deep foundation repair without a tracking planning. The proprietor accepted a 1 year review along with quarterly altitude checks at the exact same framework factors as the baseline. Our company additionally put fracture monitors on 2 internal walls that had resumed over the last and also an inclinometer on the packing dock wall.

After the very first quarter, the max rebound reduction was less than 1/16 in at some corner, properly within tolerance and most likely linked to seasonal humidity adjustment. The dock wall surface showed no quantifiable turning after the helical tieback anchors were actually locked off. Over twelve months, the retail center remained put.

Cost, timetable, and also what our company learned

We installed 186 helical piles at the border and 14 helical tieback anchors at the dock wall. Ordinary stack intensity was 32 feet. Industry creation cleared up at 8 to 12 piles every switch relying on gain access to and also pocket cutting. Total energetic development spanned nine weeks along with the fractional approach. Our experts always kept all residents available, though pair of closed at an early stage pair of evenings to make it possible for measured mounting and shop adjustments.

Owner price is constantly vulnerable, however openness helps. Helical piles are actually not the least expensive line product in a spreadsheet when reviewed to one more around of cosmetic repair services. They are, having said that, cost-effective when you amortize all of them around the steered clear of disruptions, the prevention of additional slab as well as exterior repair services, and also the market value of resident loyalty. On a job this dimension, our deep foundation scope was actually about 60 to 70 percent of total repair price, along with the equilibrium in concrete trial and also patching, bracket wallet framing, crack repair, and appearance restoration.

We also conserved time and danger through certainly not hauling boring spoils and cement, which a micropile method would certainly have required. That claimed, if the site had actually been riddled with large boulders or if the rich coating had not been reachable with coils, micropiles will have used an extra dependable road. Commercial micro pile installation shines in irregular geography. Protection piles will have operated in a case with a better reaction structure and also a defined refusal stratum closer to grade. The correct system is actually the one that harmonizes soil truths, ability, gain access to, as well as operations.

When to take into consideration options: resistance stacks and micropiles

Helical piles fit this retail job, however our company always keep various other resources all set. Resistance pile units are attractive when a structure's structure may carefully supply a reaction and also you foresee a crystal clear end-bearing disorder at shallow depths. They can be quicker in tiny volumes as well as carry out certainly not need torque relationship. The give-and-take is less insight in to ground coatings as you go and also potential variability in travel sizes that complicates planning.

Micropiles get their keep in precarious midtown websites, under massive column bunches, or even where you should permeate particles packs and also obstacles that will destroy helical leads. They supply high compressive and also flexible capacity as well as operate in both squeezing and uplift throughout a wide variety of soils. The disadvantage is actually the strategies of boring, grout, casing when needed to have, and also cure opportunity, plus the need of stringent quality control to make certain bond length efficiency. On live retail, that extra level of wet fields can easily tip the equation.

If an internet site calls for preserving wall surface adjustment beside utilities or even where dirts hang sands near quality, commercial helical tieback anchor installation offers speed along with immediate lock-off and also low mess. In clayey soils, tiebacks need cautious evaluation of creep as well as long-lasting performance, and our company occasionally point out several much shorter coil ready to spread out lots and limit creep.

Practical notes for owners as well as facility managers

- Watch water. Numerous groundwork issues on retail facilities start with irrigation versus the exterior, downspouts discharging at level, or refined adjustments in site drain after a resurfacing task. Redirecting water very early spares loan later. Measure, perform not presume. A half day along with an amount and also a strategy are going to tell you where the structure is actually relocating and just how quickly. Duplicating that questionnaire three to six months later on are going to show whether the issue is actually active. Stabilize to begin with, beautify second. Foundation crack repair on an active framework that remains to relocate is actually great funds after poor. Deep foundation repair concerns clearing away the cause. Cosmetics follow. Prepare renters. The most effective technological plan can neglect in the court of public opinion if lessees are actually shocked by sound, blocked doors, or momentary shop deglazing. Allotment the phasing, hours, and also targets. Residents will certainly aid you prosper if they feel respected. Build in tracking. Even if the repair is audio, gauging for a year gives confidence and also captures outliers. It also produces a record that sustains future purchases or even refinancing.

Technical appendix: just how we confirmed capacity

We did 2 pre-production squeezing load examinations on sacrificial helical piles installed near the most awful negotiation areas. Exam heaps connected with 34 and also 31 feet respectively, seated in the dense layer. Utilizing a center-hole port and also reaction frame bearing on temporary anchors, we packed the piles in increases to 200 percent of style. Each tests revealed flexible movement within anticipated selections and also no sign of helix bearing failure. Discharging arcs matched well with empirical torque relationships. For the tieback device, our team proof-tested every anchor to 150 percent of tasks at hand and also kept the tons for ten minutes to enjoy creep, which stayed below one tenth of an inch.

These tests gave our company assurance in the torque-to-capacity proportion our experts adopted as well as enabled a modest decrease in the aspect of safety due to the fact that our team had site-specific records. In commercial foundation repair, proof beats concept, and a few well-executed bunch examinations can easily develop the entire design.

Reflections on deep foundation repair as danger management

The push in some cases coatings deep foundation repair as a remarkable saving, but the fact is actually steadier. It is actually danger control in steel as well as torque. The selection between a helical pile, resistance pile, or even micro pile is actually a function of dirt, bunch, access, and also working constraints. In this retail center, helical piles and helical anchors matched the soil profile as well as the necessity to work gently and precisely among active store fronts. They delivered quick, verifiable capability, made it possible for measured recovery of elevations, and stabilized a filling dock wall surface that had ended up being a headache for deliveries.

The deeper session is to regard water, to determine consistently, and to act just before the hardship moves from visual appeals to construct. An experienced professional is going to show commercial foundation stabilization possibilities, certainly not a solitary prescription, and will certainly detail the pros, drawbacks, and prices in plain language. When the crew welcomes that method, the repair work carries out more than quit a crack. It returns confidence for owners and lessees, which is actually the real money in retail.